With our original and engineering works, we design new products / projects with the most appropriate quality and cost that meet the expectations of our customers.

With the DFMEA (Design Failure Modes and Effects Analysis) studies, we take the permanent precautions against the risks while we are in the design phase. With the help of our strong R&D infrastructure, we can see risks before their occurrence and we create designs that permanently prevent them from occurrence.

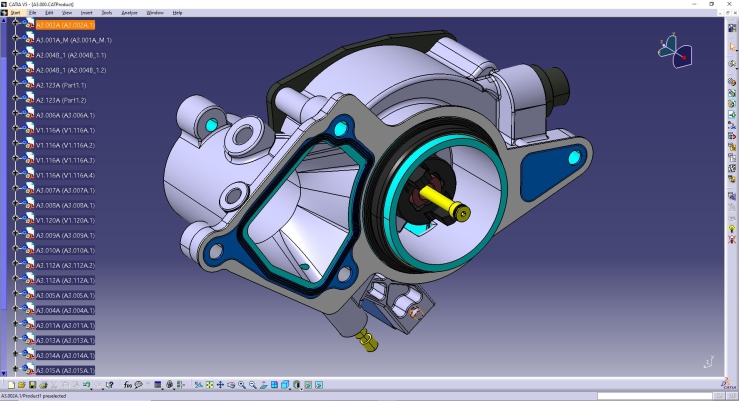

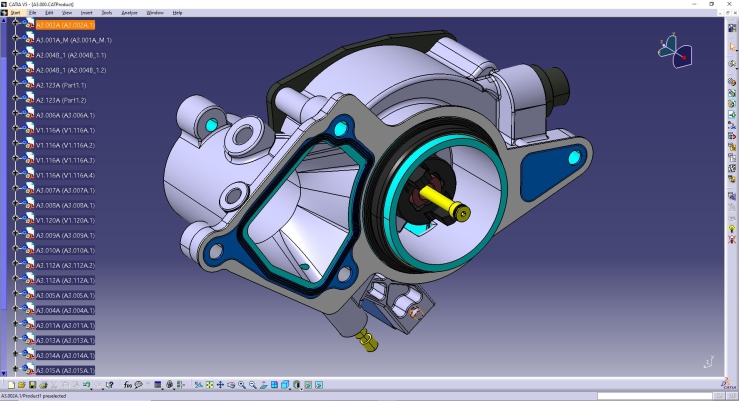

CAD/CAE software, CATIA V5 (CAD), ANSYS (CAE)  High performance computing (HPC) infrastructure

Stand for Testing the Life Cycle of Vacuum Pumps

Stand for Testing the Life Cycle of Compressors

3D Industrial FDM Printer

High performance computing (HPC) infrastructure

Stand for Testing the Life Cycle of Vacuum Pumps

Stand for Testing the Life Cycle of Compressors

3D Industrial FDM Printer

In addition, we create preliminary prototypes and we can examine the new products as a realistic output while we are still in the design phase. In this way, we follow a more realistic approach while designing our products.

With the test procedure, one of the most important points of the R&D systematic,

We can see the performance life of our designs in the test laboratory in our R&D department.

In this way, we can see the results of our new projects and evaluate them according to the desired success criteria.

We continue on our way with the determination to present brake vacuum pumps and compressors, which are the heart of the brake systems in vehicles used in the transportation and construction machinery sectors to domestic and international customers with original designs and innovations.

High performance computing (HPC) infrastructure

Stand for Testing the Life Cycle of Vacuum Pumps

Stand for Testing the Life Cycle of Compressors

3D Industrial FDM Printer

High performance computing (HPC) infrastructure

Stand for Testing the Life Cycle of Vacuum Pumps

Stand for Testing the Life Cycle of Compressors

3D Industrial FDM Printer